Logistics Consultants

Is an Independent

And Full Service

Logistics Consultancy

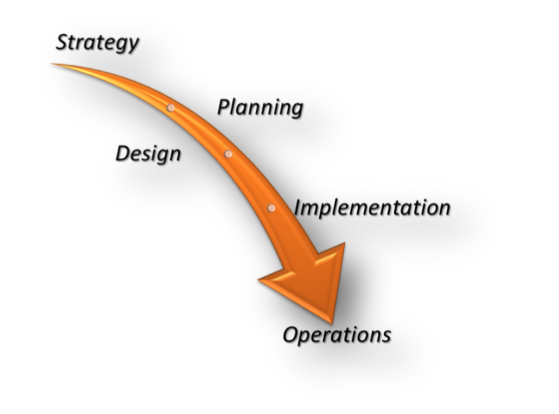

Best-Practice Solutions Are Delivered Through These Services

- Logistics Strategy Development and Network Optimization

- Distribution Center & Warehouse Layout and Plant Flow Improvement

- Industrial Material Handling Solution Design and Implementation

- Information and Control System Design and Implementation

- Operating System and Organization Design

- Training Program and Operational Assistance

Strategy Development and Master Planning

From the start we are focused on proving flexible supply chain, logistics and material handling solutions designed to meet the current and emerging needs of your business. We observe, listen and carefully document your company’s business and logistics support requirements. Using transactional data that you supply, we quickly model the current and future state. From this foundation we create a comprehensive strategy, tactics and design focused on achieving customer satisfaction and business goals.

Logistics Network Design and Optimization

The defining moment of supply chain performance is the time and place availability of products in response to customer demands for shorter lead-times and lower prices. This is all in the backdrop of aggressive competition and escalating operating cost for warehouse and distribution facilities, equipment, fuel, systems, and insurance. A logistics network optimized to improve customer service and minimize operating cost is a fundamental requirement for the winning enterprise. Determination of the network is a process incorporating strategic and tactical elements. Our methodology and use of LogicNet Plus® network modeling software provides our customer with a balanced approach to the art and science of logistics network design.

Plant, Distribution Center, and Warehouse Layout and Design

We create flexible plant, distribution center and warehouse layout models designed for plant flow improvement and to use space efficiently, effectively, and in support of EHS requirements. Whether the warehouse layout is for an existing plant, distribution facility or in a new “greenfield” facility our goal is to fit the space around the function and process vs. fitting the function and process into the space. This warehouse design and planning approach has consistently provided our customers with initial capital cost savings and lower operating cost over time. We work closely with each client’s architect or warehouse design – build construction firm to define the facility requirements for effective and efficient plant, distribution center, or warehouse designs.

Material Handling Solutions

Our experience in material handling design and implementation includes conventional and automated approaches for storage and handling system solutions. We are a leader in developing accurate and efficient approach to manufacturing, warehouse, distribution center material handling solutions including unit load, layer, case, and piece storage picking and handling systems. We have utilized many technologies including: Automated storage and retrieval, automated dispensing, pick-to-light, and radio frequency paperless solutions utilizing radio frequency communications and RFID. The warehouse and distribution systems we have designed included sophisticated conveying and high speed sorting. We are experts at designing storage systems that optimize the use of space and minimize material handling and product damage. Our clients engage us to design and implement complete warehouse and distribution system solutions that integrate material handling equipment, storage systems, warehouse management system design, automation controls, bar coding and RF identification.

Process Engineering

Process engineering is the foundation of all our warehouse logistics solutions and implementations. As industrial engineers, our focus is making sure that requirements are understood and that an operationally feasible solution is developed and implemented. At Logistics Consultants, we understand operations. The computer and material handling technologies we employ in our designs are only tools that enhance or enable effective and efficient processes. The process engineering approach permits us to explore and test alternatives on paper and in discussion with those who will use and maintain the system for years to come. Assisting our customers to build and sustain operations on the foundation of best demonstrated warehousing and distribution practices are our goal and commitment.

Warehouse Management System Design and Implementation

Proper selection, configuration and implementation of a Warehouse Management System are essential elements in planning and creation of a high performance, low cost distribution environment. The number of WMS software products is extensive. We maintain a data base of the established and emerging warehouse logistics software products and suppliers, tracking functionality, performance, cost, service, technology, reliability and customer satisfaction. We have implemented warehouse management systems on numerous hardware and operating platforms. In every warehouse management system assignment we have assisted our client’s in defining and implementing the interfaces between warehouse management system and host computers, and warehouse management system and automation control devices. In addition to WMS, our supply chain execution software selection and implementation capabilities include Yard Management Systems, Transportation Management Systems, and Labor Management Systems.

Training

We understand that even a well-conceived and designed systems will not function to its expectations if managers, supervisors and operators of the system do not have knowledge of its purposes, and are not trained to use it properly. We have developed an approach and format for education and training operational procedural and technical processes for material handling solutions and warehouse management systems that combines structured classroom and on-floor training. While each training program we develop is customized, the goal and results consistently ensure that every employee is educated, trained and practiced in the way things will work on the start-up day of the new system.